|

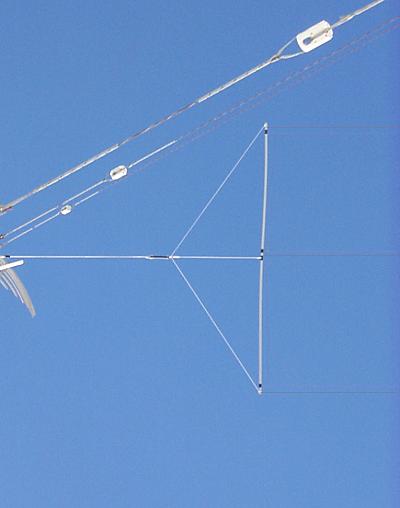

WD2XNS 137 kHz Transmit Antenna |

|

|

The Marconi transmit antenna in use at WD2XNS is easier to describe than it is to photograph! It's radiator consists of a #14 THHN vertical wire 95' tall. The top of the radiator connects to a three wire tophat suspended between two Rohn 25 towers (110' and 100' tall) that are located 100'apart. The tophat is constructed from three parallel #14 THHN wires that are spaced 5' apart and held in position by three 10' spreaders made from grey electrical PVC conduit. Overall the tophat is 10' X 85'. The three wires are joined at each end and in the middle. Care is taken to avoid any sharp bends and the wires are looped around the spreaders. These loops make effective corona rings. There is no shortage of rf voltage at the ends of the tophat! |

|

|

|

The calculated and measured antenna capacitance are in close agreement at about 547 pF. A loading coil of approximately 2.4 mH is required to tune the antenna to resonance in the 137 kHz range. The loading coil is wound on 1' diameter PVC tubing. There is an upper and lower winding each consisting of 60 turns of close spaced #14 solid THHN wire. The lower winding has a number of taps spaced 5 turns apart to allow for coarse inductance changes. Once in place, the windings are secured in position by wrapping electrical tape around the entire length of the winding. Some method should be used to hold the winding in position because the wire and coil form expand at different rates. This was learned the hard way one hot summer day when an unexpected tuning change was noticed. The unsecured coil had loosened and a number of turns had shifted and were piled up at the bottom of form. Wrapping the rewound coil with electrical tape proved to be a simple and effective fix.

|

|

|

|

|

The gray box at the lower right houses the transformer which matches the antenna resistance to 50 ohms. The transformer has a tapped primary and secondary. The two rotary switches select 12 different tap combinations that provide a matching range from 12.5 - 35 ohms up to the 50 ohm transmission line impedance. |

|

|

|

An important part of the antenna is the ground system. Careful measurements of antenna impedance (no loading coil installed) with a General Radio 516C bridge were used to optimize the ground system. The importance of using a bridge for ground system optimization can't be over emphasized. Attempting to make ground system improvements using a transmitter and rf ammeter while changing taps and tuning of the loading coil is difficult at best and likely to be innacurate. Leaving the loading coil and transmitter out of the picture a more accurate measurment of the ground system is possible. The bridge will immediately confirm if the changes to the ground system reduced the resistance or not. |

|

| Back to WD2XNS home page |